A leading home appliance customer recently approached Zettler Group’s display division to help enhance their product appearance of a display device featuring a cover glass attached to a TFT display unit. The customer needed to get the cover glass bonded with a TFT in such way that the entire surface was to appear uniformly black (“all-black” effect) when the device is in power-off mode.

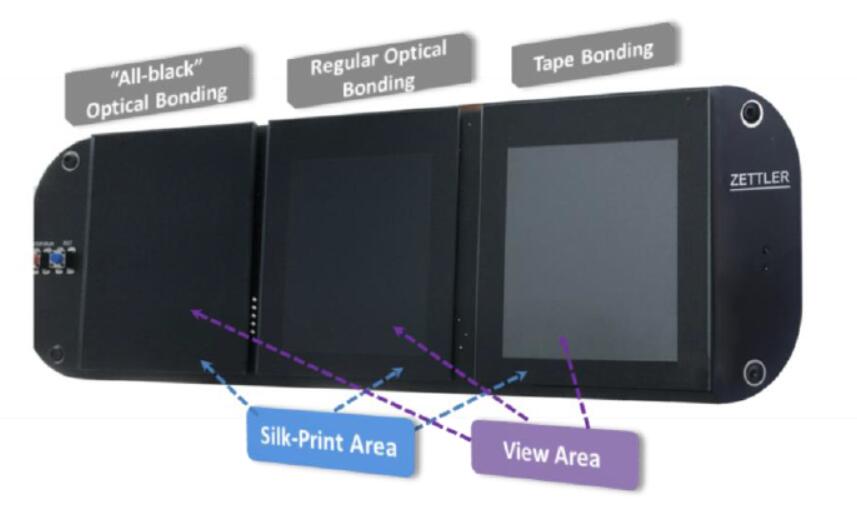

Touch Panels or plain Cover Glass mostly feature a a black color silk print on the non-view (inactive) area of the cover glass. Due to light transmission and reflection rate difference between the silk print non-view area and the view area of the TFT, both areas effectively appear in two different shades when looking at the whole display unit in power-off mode. The shades depend on the bonding method used. The black color of the silk print contrasts with either a gray color of the view area (when using tape bonding) or a lighter black color (when using regular optical bonding).

ZETTLER Displays successfully provided a special optical bonding solution to the customer to accommodate the requirement for a uniform “all-black” effect by combining suitable materials with special process technology. This treatment is suitable for indoor applications and currently provide such special optical bonding for product sizes up to 3.5”.

From a straight viewing (orthogonal) direction, the entire surface visually appears as one homogenous piece of black color cover glass. The image below shows the comparison of visual effects (power-off) of different bonding processes compared to the “all-black” solution.

About Optical Bonding

We have capabilities to provide various forms of bonding of TFT modules to be attached to Touch Panels (TP) or Cover glass (CG); either a Tape bonding or Optical bonding process can be adopted.

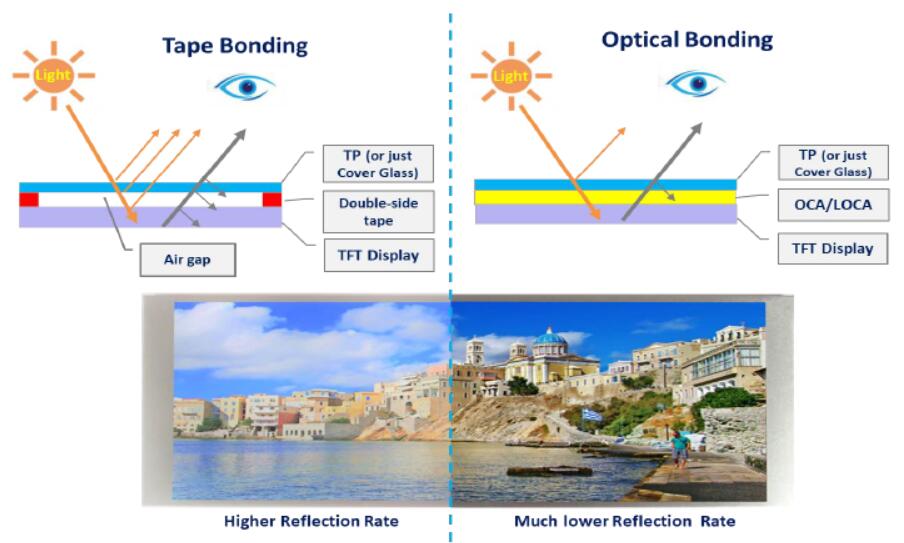

In Tape bonding a TP or CG is attached to a TFT with adhesive tape by the edges of the screen glass. In Optical Bonding the TP or CG is glued to the LCD panel with either OCA or LOCA adhesive to completely fill the air gap between them.

Optical bonding improves the overall performance for the displays and is increasingly popular in both consumer and industrial applications. The illustration and comparison of two bonding processes are shown below.

Tape Bonding | Optical Bonding | |

Advantage | 1. Easier to process with higher yield rate. | 1. Improved viewing experience by eliminating the illusion of pixel shift caused by air gaps - results in improved contrast and wider viewing angles. |

Tape Bonding | Optical Bonding | |

Disadvantage | 1. Air gap between TP (or CG) and LCD can cause glare and will cloud the image on the LCD reducing the visual performance -especially in brighter environments. | 1. OCA/LOCA materials and process are more costly and optical bonding yield rate is lower and difficult to rework- especially for LOCA bonding which can handle the bonding for rugged/curved surface glass. 2. More complex in process and lower yield rate. |